Intralogistics is increasingly becoming a crucial component of logistics planning, offering organizations the chance to revolutionize how they bring their goods and services to customers. A focus on intralogistics helps to keep businesses competitive by reducing supply chain costs, streamlining inventory management and maintaining operational efficiency. In this article, we will be examining the following:

- What is intralogistics?

- What is the market outlook for intralogistics?

- How do intralogistics work and examples of such activities within the logistics planning process?

- What benefits does the implementation of intralogistics bring to supply chain management?

- How can barcode technology assist in intralogistics?

- Conclusion

What is intralogistics?

Definition of intralogistics

In short, intralogistics is a term used to describe the movement of information, raw materials, and inventories within an organization. It is used to describe all internal supply chain operations, from the management of raw materials to the dispatch of these items to the production line and shipment to customers.

Emergence of Intralogistics 4.0

Today, the rise of new technologies has paved the way for the emergence of Intralogistics 4.0. This revolutionary concept revolves around harnessing the power of automated guided vehicles (AGVs), conveyor systems, and warehouse management systems (WMS) to streamline supply chain operations. Furthermore, Intralogistics 4.0 involves integrating various control systems, such as WMS and enterprise resource planning (ERP), to provide comprehensive visibility into all aspects of intralogistics operations.

In the following sections, we will delve deeper into the utilization of these advanced technologies in intralogistics.

What is the market outlook for intralogistics?

Future outlook of intralogistics

The global intralogistics market is expected to experience significant growth, with a projected compound annual growth rate (CAGR) of 14.8%. By 2032, the market is estimated to reach $75.36 billion, up from $18.94 billion in 2022.

This remarkable expansion is primarily driven by the adoption of Intralogistics 4.0 technologies, which enable organizations to streamline and enhance their warehouse processes and logistical operations. Additionally, the growing e-commerce industry and increasing demand for automated warehouses are set to further propel the growth of the intralogistics market.

Adoption of Intralogistics 4.0 technologies

The adoption of Intralogistics 4.0 technologies is the primary driver of market growth. Some examples include the use of AGVs for material movement with little human intervention. Others include automated storage and retrieval systems (AS/RS) where with the help of computer-controlled systems, the retrieval and storage of loads from defined storage locations are fully automated.

Such new-age solutions bring about unprecedented levels of automation and efficiency to logistics services, allowing businesses to reduce supply chain costs, enhance inventory accuracy and minimize stock discrepancies.

Growth of the e-commerce Industry

The rapid growth of the e-commerce industry has also significantly contributed to the proliferation of intralogistics solutions. The global e-commerce market is valued at $9.09 trillion in 2019 and is expected to grow CAGR of 14.7% from 2020 to 2027.

With consumers increasingly turning to online shopping for convenience, businesses are increasingly investing in infrastructure and technology to efficiently manage their warehouses. As such, the demand for intralogistics solutions is expected to rise in tandem with the growth of the e-commerce industry.

Next, we will explore how intralogistics work and examples of such activities.

How do intralogistics work and examples of such activities within the logistics planning process?

The goal of intralogistics is to focus on the optimization of logistics processes. This includes everything from the moment goods arrive at the warehouse, through their storage, processes, and movement around the facility, to their eventual dispatch within the supply chain process.

Some key intralogistics activities that fall under the umbrella of logistics planning include:

Internal material flow:

This refers to the systematic flow of goods from their source to their destination. This includes the transportation of materials and products within warehouses, retail stores, and other facilities. By optimizing internal material flow, companies can reduce lead times and increase revenue.

Information flow and inventories management:

The efficient flow of information and real-time inventory management are vital parts of intralogistics. By having a complete overview of the supply chain and the ability to adjust inventory levels in response to demand, organizations can greatly reduce storage costs and satisfy customer demands while withstand supply chain disruptions.

The utilization of automatic identification technologies, including barcode systems and RFID systems, plays a vital role in facilitating the real-time information flow across the supply chain. For instance, QR codes encode information that can be swiftly scanned and transmitted to a warehouse management system or ERP system. This data can then be leveraged to make informed decisions regarding inventory control and transportation scheduling, ensuring cost-effective logistics planning.

Warehouse management:

Warehouse management is a key component of intralogistics activity. Warehouse management systems (WMS) are used to manage and control the movement and storage of materials within an organization. Besides, WMS provides valuable data for performance analysis, helping to identify areas for improvement and optimize warehouse operations.

Other than having a state-of-the-art WMS in place, an effective warehouse management system also relies heavily on the integration of other technologies. Innovations like automated storage and retrieval systems (AS/RS), RFID systems, and barcode scanning have revolutionized traditional warehouse functions. By streamlining processes and minimizing errors, these advanced technologies enhance the intralogistics processes while reducing the chances of unexpected disruptions.

In the next section, we will delve into the benefits of adopting intralogistics.

What benefits does the implementation of intralogistics bring to supply chain management?

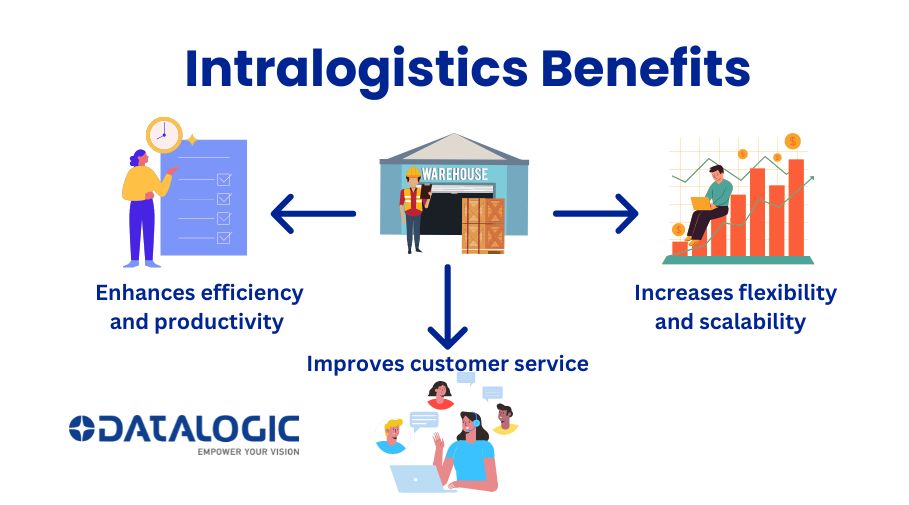

Adopting intralogistics within supply chain management yields several significant benefits:

Enhances efficiency and productivity:

By optimizing internal processes and minimizing manual labour, intralogistics greatly boosts efficiency and productivity. Advanced technological systems can outperform humans in terms of speed and accuracy, leading to cost reductions, including shipping costs. Additionally, operations become faster while the risk of costly errors decreases.

Improves customer service:

With real-time tracking and efficient inventory management, intralogistics can greatly enhance an organization’s capacity to meet customer demand and deliver prompt, accurate service. This, in turn, has the potential to elevate consumer expectations and foster loyalty, ultimately resulting in increased sales and positive word-of-mouth.

Increases flexibility and scalability:

Intralogistics offers exceptional scalability and flexibility, making it an optimal solution for businesses of any size. As organizations expand, intralogistics systems can effortlessly adjust to meet growing demands, eliminating the need for substantial investments in infrastructure or human resources. These remarkable capabilities transform it into an indispensable tool for organizations aiming to enhance their production lines and operations, ensuring optimized efficiency at every step.

From the above, it is clear intralogistics offers tangible benefits for organizations in their logistics planning. By deploying advanced technologies, organizations can gain a competitive edge by enhancing efficiency and productivity, and improving customer service while increasing flexibility and scalability.

How can barcode technology assist in intralogistics?

Pivotal role of barcode technology

Barcode technology plays a pivotal role in improving intralogistics processes. This technology allows for fast, efficient, and accurate tracking of assets within the supply chain, from the moment goods enter the warehouse until their eventual dispatch.

By attaching a universal product code to products, machines, or even specific areas within a warehouse, scanning them with barcode scanners enables swift data collection, minimizing the possibility of human error. This system can seamlessly integrate with an inventory management system to provide real-time inventory tracking, resulting in heightened precision in stock levels and assisting in the prevention of overstocking or stock-outs.

Moreover, barcode technology accelerates the picking process by providing detailed location information of the items to be picked, thereby reducing the time workers spend searching for items. It also helps in the verification process, ensuring the correct items are picked and dispatched.

Furthermore, by automating the tracking of goods, barcode technology also allows for in-depth analysis of an organization’s logistics processes. This data can be used to identify bottlenecks, inefficiencies, or areas that need improvement, thus creating opportunities for further optimization of logistics operations.

In conclusion, barcode technology is an essential tool for modern logistics planning, offering a multitude of benefits that can significantly enhance the efficiency and accuracy of logistics operations.

Conclusion

Intralogistics, a crucial element of logistics planning, plays a pivotal role in modern supply chain management. By harnessing advanced technologies such as warehouse management systems, automated storage and retrieval systems, and barcode scanning, it enhances operational efficiency, elevates customer service, and enables scalability.

Embracing intralogistics not only streamlines internal processes but also empowers organizations to meet the ever-increasing demands of a dynamic marketplace. It is evident that in an era defined by technological advancements and heightened customer expectations, intralogistics remains an indispensable driver of success in logistics planning.

Do reach out to our Datalogic experts for more information for intralogistics solutions.